Custom Eco-Friendly Cosmetic Bottle Manufacturer

Professional Silk Screen Printing & Finishing

Custom Eco-Friendly Cosmetic Bottle Manufacturer

Professional Silk Screen Printing & Finishing

Company Overview

Guangzhou Yiyuan, established in 2008, has been dedicated to the beauty packaging industry for 17 years. It is one of the earliest modern enterprises in China specializing in high-end cosmetic container manufacturing. Leveraging our full-chain capabilities of development, production, processing, and sales, we focus on the customized development and precision manufacturing of various high-end perfume bottles, perfume caps, cosmetic bottles, and cosmetic caps. Our products are widely used by international luxury beauty brands, domestic emerging makeup brands, and premium cosmetic lines. We cater to a variety of packaging needs, including standard products, limited editions, and gift sets, providing clients with a one-stop beauty packaging solution from creative design to final product delivery.

Main Products

Our company focuses on high-end, customized, and scenario-based product development, offering tailored designs and processes according to client requirements. Perfume Bottles (Glass) Made from high-transparency borosilicate glass or crystal glass. Supports clear, frosted, or colored customization, combined with spraying, hot stamping, and other finishing techniques. Available in cylindrical, square, or special-shaped bottles, suitable for luxury fragrances, high-end salon perfumes, and premium perfumery. Perfume Caps Materials include metals (aluminum alloy, zinc alloy), acrylic, and ABS. Supports electroplating, hot stamping, and features twist-on or press-on styles. Built-in silicone sealing rings and customizable embossed logos ensure functionality and branding. Serum / Ampoule Bottles Available in glass (light-protective for active ingredients) or PETG. Compatible with droppers or press pumps with anti-mistouch locks. Capacity ranges from 5–50ml, suitable for ampoules and high-end serums. Lotion / Cream Bottles Includes wide-mouth jars (with spatulas and dustproof caps) and pump bottles (with twist-lock design). Materials include ABS + acrylic and glass. Supports multi-color spraying for premium cosmetic presentation. Universal Cosmetic Caps Compatible with round, square, and special-shaped bottles. Materials include metal, plastic, and acrylic. Supports oil spraying and water transfer printing, meeting styles from Instagram aesthetics to vintage luxury looks.

Core Competencies

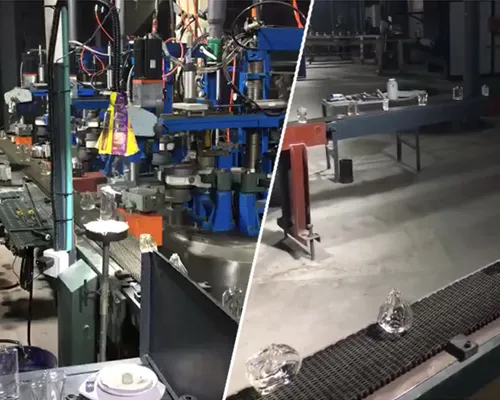

Extensive Experience With 17 years of expertise in cosmetic packaging, we are well-versed in packaging regulations across different regions, including the EU, the United States, and Southeast Asia. We assist clients in avoiding compliance risks and ensuring their products meet international standards. Production Capacity Our factory covers approximately 8,000㎡ and is equipped with 5 automated production lines, with an annual output of 50 million cosmetic containers. We can handle orders ranging from small batches of several hundred units to large-scale orders of hundreds of thousands, with a maximum delivery cycle of 15 days. R&D Strength We hold 3 utility model patents, including “Scratch-Resistant Cosmetic Bottle Spraying Process” and “High-Precision Screen Printing Device for Special-Shaped Bottles,” continuously driving innovation in our processes. Environmental Commitment We use eco-friendly coatings and inks that comply with EU REACH and US FDA standards. Spray emissions are treated via RTO incineration to meet environmental discharge standards, demonstrating our commitment to sustainable production.

Key Equipment and Manufacturing Capabilities

Our factory is equipped with state-of-the-art intelligent production and processing equipment, all using imported control systems to ensure precision and stability: Automated Spraying Lines Featuring electrostatic spraying technology and constant-temperature drying systems. Coating uniformity exceeds 98%, supporting over 20 finishes including matte, pearlescent, metallic, and gradient effects. Coating adhesion meets international ASTM standards, with 100% pass rate in friction and alcohol resistance tests. Screen Printing / Pad Printing Equipment Equipped with high-precision CCD alignment systems. Minimum screen printing accuracy reaches 0.1mm, enabling complex patterns, fine text, and multi-color printing. Compatible with round, square, and special-shaped bottles. Maximum pad printing area per pass: 150mm × 80mm. Hot Stamping / Foiling Machines Supports both cold and hot stamping processes. Can apply gold, silver, holographic, and iridescent foils with sharp edges and strong adhesion. Ideal for precise logo decoration on luxury perfume caps and bottles. Glass Polishing Machines Using diamond grinding wheels for fine polishing, capable of mirror finishing bottle mouths and edges. Surface roughness Ra ≤ 0.8μm, effectively eliminating burrs, scratches, and other imperfections, enhancing product texture. Leveraging these advanced systems, we offer full-process surface finishing services, including spraying, screen printing, pad printing, heat transfer, decal application, and glass polishing. Our heat transfer process enables 360° wrap-around printing, perfectly solving pattern printing challenges on irregularly shaped bottles, meeting clients’ demands for personalized and high-end cosmetic packaging.

Quality Philosophy & Service Commitment

Our company always upholds the principle of “Quality First, Market-Oriented, Customer-Centric”, integrating quality management throughout the entire production process. Quality Control System We have established a three-tier quality control process: Incoming Material Inspection (IQC) → In-Process Inspection (IPQC, sampling every 2 hours) → Final Product Inspection (FQC, 100% appearance check + sampled performance testing). Inspection reports are retained for every batch, and defect rates are strictly controlled below 0.5%. Technical Support Our team includes 22 senior engineers with over 10 years of experience in the cosmetic packaging industry, 5 of whom hold national intermediate engineer titles. We provide full-process technical support, from product structure design and process optimization to sample prototyping. Sample production can be completed in as little as 3 days, helping clients accelerate product development. Market Adaptation We closely monitor cosmetic packaging trends and regularly update equipment and processes, investing approximately 6% of annual revenue in technology upgrades. Our capabilities cover a wide range of materials, including glass, ABS, PET, and acrylic, meeting diverse brand requirements for material, cost, and environmental standards. By combining standardized quality control with customized technical services, we ensure high-quality, timely, and adaptable products for our clients. To date, we have served over 300 domestic and international customers, with a repeat purchase rate exceeding 75%, earning broad recognition within the industry.